News

The Joint Methods of PTFE Mesh Conveyor Belt

发布时间 : 2018-12-12 浏览次数 : 次

PTFE mesh conveyor belt, also known as PTFE open mesh conveyor belt, is a new type of composite material in the market. In order to meet the market trends and the customers’ requirements, several types of joints has been developed as bellows:

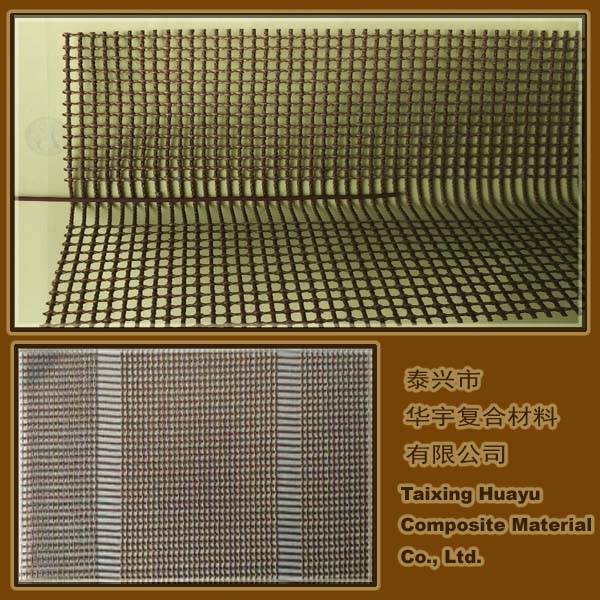

Kevlar bull-nose joint is made of Kevlar yarn and fiber yarn coated with PTFE resin after weaving. It has high strength and good wear resistance. It is mainly used for PTFE mesh conveyor belts and occasionally for PTFE coated fiberglass conveyor belts. The general specification is 4×4MM in mesh size.

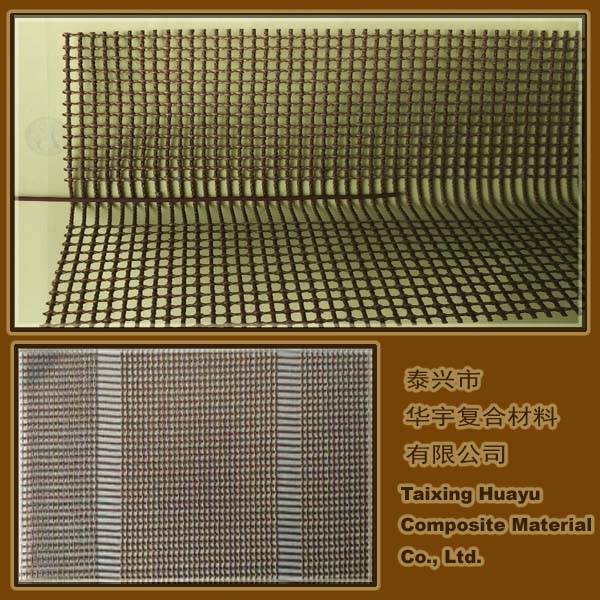

Wall joint is made of Kevlar fabric, which is a composite material coated with PTFE emulsion. It is characterized by high tensile strength, good wear resistance, high temperature resistance and anti-sticking. It is mainly used for PTFE mesh conveyor belt and PTFE coated fiberglass conveyor belt.

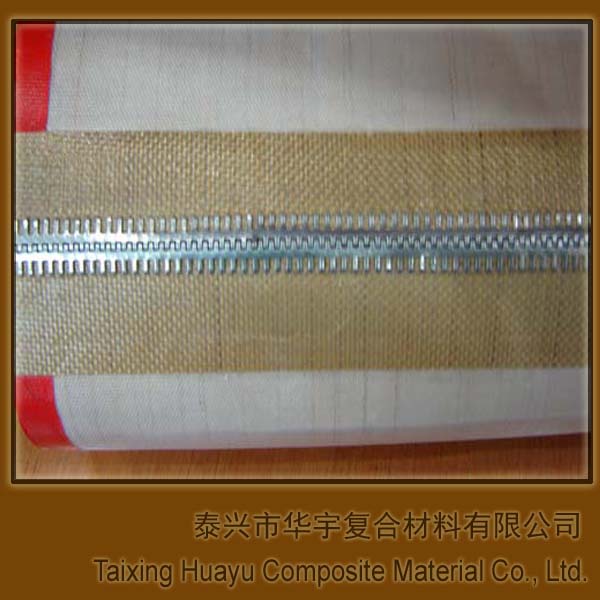

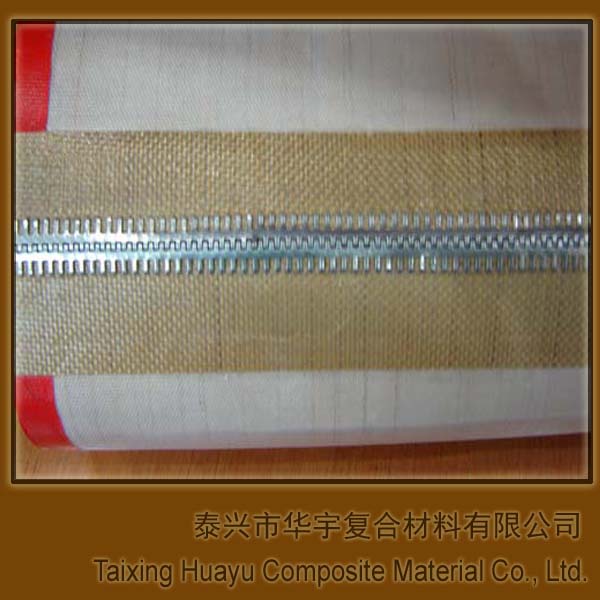

Steel buckle joint is made of stainless steel. If used in PTFE mesh conveyor belt and PTFE coated fiberglass conveyor belt, it needs to be used together with Kevlar fabric. Since the steel buckle joints need manual operation, the production cost is very high, and the general customer recommends using the Kevlar bull-nose joint.

Kevlar bull-nose joint is made of Kevlar yarn and fiber yarn coated with PTFE resin after weaving. It has high strength and good wear resistance. It is mainly used for PTFE mesh conveyor belts and occasionally for PTFE coated fiberglass conveyor belts. The general specification is 4×4MM in mesh size.

Wall joint is made of Kevlar fabric, which is a composite material coated with PTFE emulsion. It is characterized by high tensile strength, good wear resistance, high temperature resistance and anti-sticking. It is mainly used for PTFE mesh conveyor belt and PTFE coated fiberglass conveyor belt.

Steel buckle joint is made of stainless steel. If used in PTFE mesh conveyor belt and PTFE coated fiberglass conveyor belt, it needs to be used together with Kevlar fabric. Since the steel buckle joints need manual operation, the production cost is very high, and the general customer recommends using the Kevlar bull-nose joint.